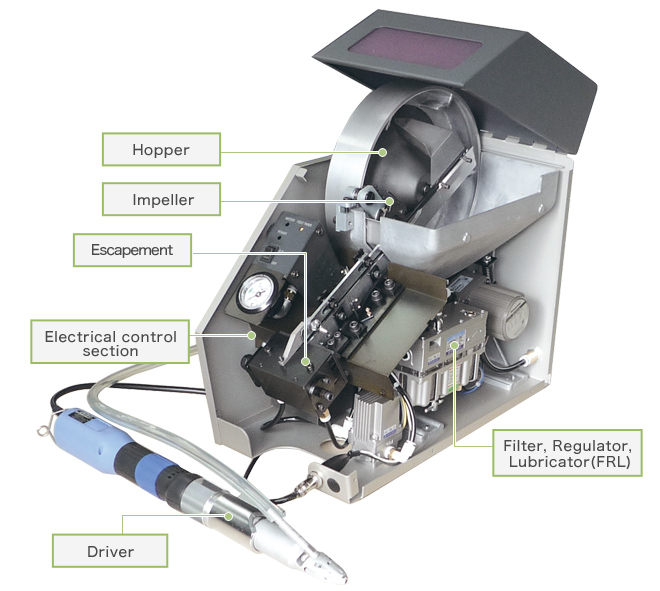

The VIS SETTER Handy <auto screw fastener> has the following major parts and functions.

-

Hopper

Screws matching the VIS SETTER model are loaded screws into the hopper where screws are stored for use. The loaded screws are rotated by a vane inside the drum to supply them to the chute.

-

Impeller

The rotating action of the impeller mounted in the chute passes the screws along while making them face the right direction and sends screws that can't be aligned back to the hopper.

-

Escapement

The escapement for sorting and feeding screws one at a time is integrated with 2 chutes for different screw diameters and is important for maintaining auto screw fastener reliability.

-

Electrical control section

This is a compact control box incorporating a screw feed control circuit. This section is essential for ensuring dependable screw fastening operation.

-

Driver

This section is gripped by the hand during screw fastening. Both pneumatic or electrical drivers are available. The type and size of driver can be selected to match the screw fastening conditions.

-

Filter, Regulator, Lubricator(FRL)

This section controls the supply of compressed air for feeding screws to the escapement or as power for rotating the driver.